Unlocking Efficiency and Innovation: Adhunik Powertech's

20 Years of HVAC Excellence

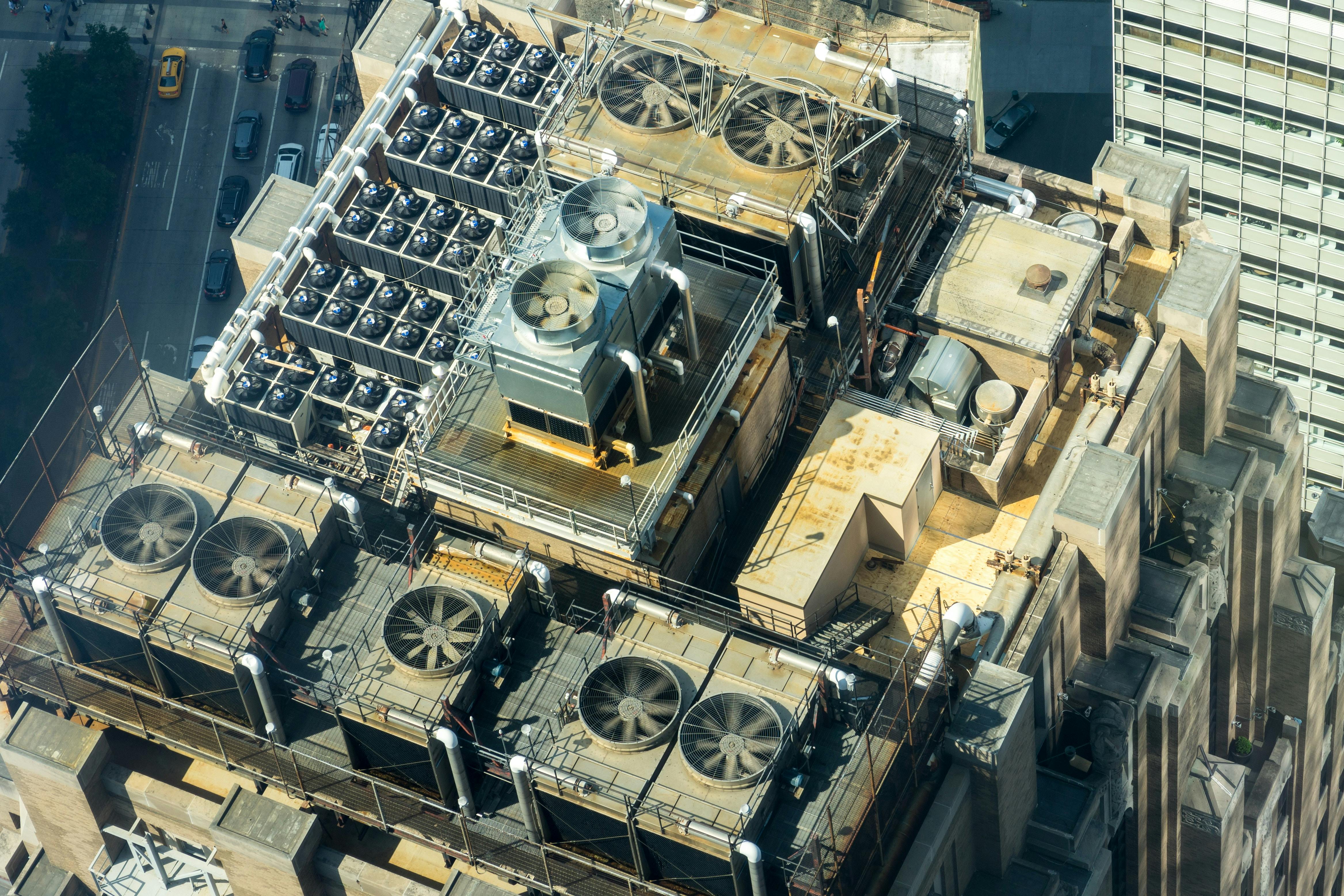

For two decades, Adhunik Powertech has been at the forefront of the Heating, Ventilation, and Air Conditioning (HVAC) industry, consistently delivering cutting-edge solutions and setting benchmarks for excellence. With 20 years of extensive experience, we've not only witnessed the evolution of HVAC technology but have actively contributed to shaping its future.

At Adhunik Powertech, we believe in empowering our clients and the broader industry with knowledge. That's why we're sharing some invaluable insights and the fundamental principles that guide our projects, reflecting our deep understanding and commitment to innovation in HVAC.

The Core of HVAC

The Core of HVAC : Essential

Thumb Rules & Formulas We Live By

Effective HVAC design isn't just about installing equipment; it's about meticulous planning, precise calculations, and an in-depth understanding of environmental factors. Here are some critical thumb rules and formulas that form the bedrock of our HVAC solutions :

Heat Load Calculation

CFM Calculation

Chilled Water Flow Rate

Chiller Sizing & Cooling Towers

Duct and Pipe Sizing

Clean Room Classifications & Air Changes Per Hour (ACH)

- Operation Theaters (OT) : 20–25 ACH

- ISO 7 Cleanrooms : 60–90 ACH These high ACH rates, combined with sophisticated filtration, ensure that airborne contaminants are rapidly flushed out, maintaining the required cleanliness levels.

HEPA Filter Design

Room Pressure Differentials

Controlling Contamination Pathways: Maintaining precise pressure gradients is vital to prevent cross-contamination. We design systems to ensure

- Positive Pressure : For sterile environments like OTs (+10 to +15 Pa) and ICU/NICUs (+5 to +10 Pa) relative to corridors, preventing the ingress of unfiltered air.

- Negative Pressure : For isolation rooms (-10 to -15 Pa), containing airborne pathogens within the space.

Laminar Airflow & Environmental Control

In critical zones, such as above surgical tables, we implement unidirectional (laminar) airflow at velocities like 90±20 ft/min, creating a clean "air curtain." Furthermore, precise temperature and humidity control are non-negotiable

- OTs : 21–24∘C with 50–60% RH

- Pharma Cleanrooms : 20–22∘C with 45–55% RH These parameters are crucial for patient safety, product integrity, and preventing microbial growth.

Real-Life Impact:

Critical Environments

Adhunik Powertech's expertise extends far beyond standard comfort cooling. For two decades, we've specialized in designing and implementing HVAC systems for highly sensitive environments like hospitals and pharmaceutical clean rooms, where precision, contamination control, and strict regulatory compliance are non-negotiable.

Here’s a glimpse into our specialized knowledge for these critical applications:

Beyond Comfort: HVAC in

Critical Environments

Adhunik Powertech's expertise extends far beyond standard comfort cooling. For two decades, we've specialized in designing and implementing HVAC systems for highly sensitive environments like hospitals and pharmaceutical clean rooms, where precision, contamination control, and strict regulatory compliance are non-negotiable.

Here’s a glimpse into our specialized knowledge for these critical applications:

Case Study 1

Transforming a Commercial Hub in Gurugram A prominent commercial tower in Gurugram faced escalating energy bills and inconsistent cooling across its vast office spaces. Adhunik Powertech conducted a comprehensive energy audit and implemented a Variable Refrigerant Flow (VRF) system, meticulously designed after calculating precise heat loads for each zone. We optimized the ducting and air distribution, ensuring uniform comfort. The result? A 25% reduction in annual energy consumption for HVAC, significantly lowering operational costs and improving tenant satisfaction, making the building more attractive to high-profile businesses

Case Study 2

Ensuring Sterile Environments in a Delhi Hospital For a leading multi-specialty hospital in Delhi, maintaining stringent air quality in their new surgical wing was critical. Adhunik Powertech designed and installed a specialized HVAC system incorporating multiple stages of filtration, including HEPA filters for all Operation Theaters. We implemented precise positive pressure regimes in OTs (+12 Pa) relative to corridors, ensuring no contaminated air could enter. Our rigorous validation processes, including particle counts and airflow velocity tests, confirmed compliance with ISO 7 standards, directly contributing to reduced post-operative infection rates and enhanced patient safety.

Case Study 3

Precision Control for a Pharmaceutical Plant in Hyderabad A pharmaceutical manufacturing facility in Hyderabad required an HVAC system capable of maintaining extremely tight temperature and humidity controls for its API (Active Pharmaceutical Ingredient) production area, specifically a low-humidity cleanroom. Adhunik Powertech engineered a solution that maintained temperatures at a consistent 21∘C and relative humidity at 48% with a deviation of less than ±2%, using specialized desiccant dehumidifiers and high-precision controls. This enabled the client to ensure product stability and meet strict international pharmaceutical regulations (GMP), safeguarding their product quality and market access.

Two Decades of Trust

and Innovation

Our 20-year journey has been defined by a relentless pursuit of excellence and a commitment to understanding the unique needs of every project. From optimizing energy consumption in commercial buildings to designing hyper-sterile environments for healthcare, Adhunik Powertech leverages its extensive experience, cutting-edge technology, and a deep well of technical knowledge to deliver superior HVAC solutions.

We don't just build systems; we build partnerships, ensuring that our clients benefit from enhanced operational efficiency, reduced running costs, and environments that are perfectly tailored to their purpose. Our legacy is built on the tangible impact we make on the organizations we work with, helping them unlock their true potential and stay ahead in the ever-evolving digital and industrial landscape.

Get Expert Advice for Your Cooling Needs

Ready to experience the Adhunik Powertech difference? Contact us today to discuss your next HVAC challenge, and let our two decades of expertise work for you.